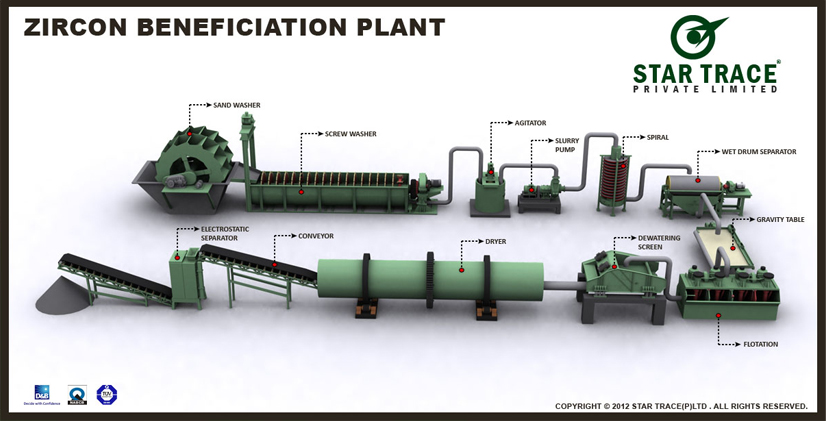

Zircon Beneficiation Plant

Star Trace offers turnkey solutions for zircon benefication plants. We are one of the leading project suppliers for zircon plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of Zircon Beneficiation plant & equipment.

Sand Washers

Sand Washer machine is used to remove dust in sand. It aims at improving the quality of sand. It has the characters of a high degree of cleaning reasonalble structure, large output and a small loss of sand during the washing.

ApplicationsSand washer machine cleaning materials is widely utilized in the following industries quarries, mineral deposits, building materials, transportation, chemical business, water conservancy and hydropower, concrete mixing station, sand stone ore, building sites, gravel plant, hydropower train station dam site.

And with higher cleaning action features, reasonable framework, large capacity, low power usage, small loss of sand within the washing process, especially for the sand washer drive is separated from drinking water and sand.

Therefore, it may be less than the failure rate from the usual sand washing machine.

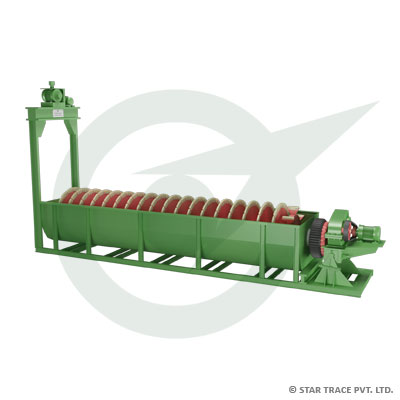

Screw Washers

Screw sand washing machine is mainly used for sand processing, electric pole factory, building work site and concrete dam, various sands classifying and dewatering.

The Screw Washer adopts inclination 15°, under the water tub, three weir plates form the sediment pool, the screw head is immersed in this pool, the screw is driven by electric motor through reducer rotating continuously, the fresh water is feeding from porous plate at bottom of sediment pool, this machine have three functions of washing, dewatering, classifying.

Agitator

Agitation tank is the necessary equipment that regularly mixes the drugs and slurry, increases pharmaceutical drug reactions.

Agitation tank uses motor V-belt driving impeller to rotate. Regularly mixes the drugs and slurry, increases the role of pharmaceutical drug reactions and enhances the quality reaction time.

This machine applies to the mining dressing and also used as a variety of chemical industry trough cake mix.

Slurry Pumps

STAR TRACE is one of the most well recognized manufacturers of heavy duty, medium duty slurry and process pumps, vertical slurry pumps, ash slurry pumps, process pumps in India today.

Our company manufacturers advanced slurry pumps and process pumps. Our pump handle tougher abrasive solids and slurry found in mining, steel and glass industries.

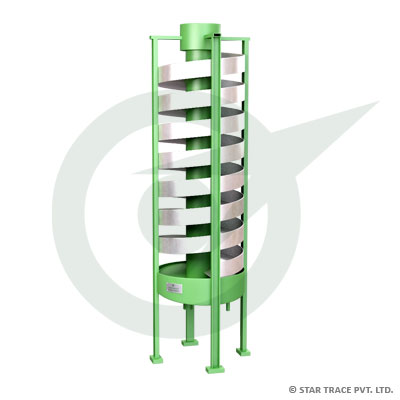

Spiral Separators

Spirals are gravity concentrators and separate minerals of different specific gravity according to their relative movement in response to gravity, centrifugal force and other forces in the fluid medium. It has extremely good performance and effects in processing placer of beach, riverside, seashore and stream.

STAR TRACE spirals are made of polyurethane lined fiber glass with wearable corundum inner surface. Generally there are 5 turns in one start, single, twin, triple and quad starts available per column to suit capacity requirements.

Applications- Rutile, ilmenite and zircon concentration.

- Iron ore, chromite and manganese beneficiation.

- Tin, tantalum and ore concentration.

- Gold, native copper and base metal recovery.

- Silica sands processing.

- Titano-magnetite concentration.

Wet Drum Magnetic Separator

STAR TRACE Wet Permanent Magnetic Separators are offered in sizes of Dia 1200mm and 916mm in length of up to 3000mm. Three basic separator designs are available for cobbing, roughing and finishing /cleaning applications.

Each type can be supplied in a single drum or multiple drum stages for taconite or magnetite and also for recovery for magnetic medium in dense media plants. The stationary magnet yoke is an assembly of strontium-ferrite permanent magnets. The rotating drum is available with optional rubber or stainless steel covers. The magnetic flux pattern will match the tank configuration for optimum performance.

Star Trace magnetic wet separator dia 916 x 300mm is the smallest full scale separator in the 916 series and is primarily used for pilot plant tests. The separator can be delivered in concurrent, countercurrent and counter rotation versions.

Star Trace magnetic wet separator for laboratory use have drum dimensions dia. 600 x 285mm and dia. 200 x 100mm and dia are suitable for batch or continuous testing. The test results from the STAR TRACE laboratory separators correspond closely to those obtained in full scale operation.

Gravity Tables

Head Motion:

The head motion is of rugged construction and requires minimum maintenance. Its internal mechanism is splash lubricated from an integral oil sump.

Decks:The decks are built of 16mm zircon-reinforced fiberglass with fabricated steel frames at the bottom and are easy to clean, requiring little maintenance. The specific gravity of fiberglass made into decks is one third of that of steel, while its strength reaches as high as 70% that of steel. This fiberglass deskc also has the characteristic of water-resistance and corrosion -resistance and can hold the shape unchangeable at ±50°C.

Gravity Tables are designed to wet gravity based separation of minerals and other granular materials. There are many applications where the gravity table is of particular value and cannot be equalled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals.

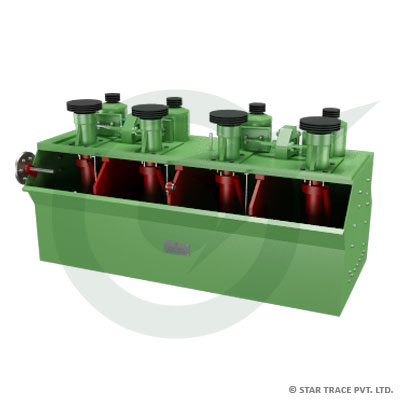

Floatation Machine

STAR TRACE designs and manufactures all sizes of flotation cells. Multiple impeller/diffuser configuration can be used to either enhance or restrain mixing depending upon the nature of the ore being treated.

The robust design allows the structure to be self-supporting and thus fewer supporting beams are requires for installation. Metallurgically the hydrodynamic shape eliminates short-circuiting and prevents sanding.

Specially profiled impellers and diffusers enhance efficient pumping of the slurry. Excellent dispersion of the external air feed and homogeneous mixing of the air and slurry all contribute to superior recoveries and grades being obtained. The impellers and diffusers are moulded rubber or polyurethane coated for abrasion resistance.

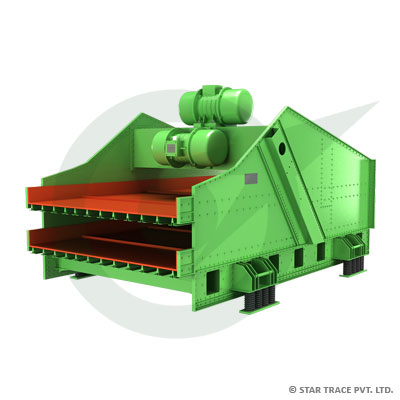

Dewatering Screen

We offer a high quality Dewatering Feeder which is used in various applications.

Features of Dewatering Feeders:- 900 x 1400mm dewatering feeder driven by two overhead mounted vibratory motors and single polyurethane drainage panels.

- Head feed to mineral processing equipments often contains excessive moisture adversely affecting the performance of such equipment.

- Star Trace dewatering feeders are designed to fulfill two basic requirements, remove the excess moisture and regulate the feed rate of the processing equipment.

- Polyurethane or stainless steel wedge wire screen panels on the feeder pan allow the water to pass through, drying the solids in the feed.

- The vibratory motors can either be mounted below and to the rear of the pan or overhead. Overhead mounting allows maximum area of drainage panel.

- The standard range of screen from 300mm x 900mm to 3000mm x 9000mm in single deck configuration.

Dryer

The dryer comes to be a product of excellent industrial utility that stays consistent year after year.

Composed from highly durable material, our outputs have been meeting industrial levels of perfection throughout.

Our client feedback system has been very successful at delivering premium quality outputs of our products.

Electrostatic Drum / Plate Separator

Star Trace is a well established company actively engaged designing, developing and supplying top notch High Tension Electrostatic Drum/Plate Separator as per customer’s requirements.

Our engineers offer latest deigns of high tension drum/plate separators which are suitable for various industrial applications.

These products are designed for separating mixtures of bulk materials, which are differing by their electrical properties.

Our high performing high tension drum/plate separators are manufactured by following international quality norms and standards to satisfy the customers at market leading prices.

We design and develop high tension drum/plate separators with following features matching with customer’s requirements.

This separator is capable of producing high grade concentrators with fast recovery of valuables owing to three step re-cleaning and facility for heating materials. In addition, it also consumes little electric power and is environment-friendly.